Project Habakkuk

The Extraordinary Story of Britain's Ice Aircraft Carrier

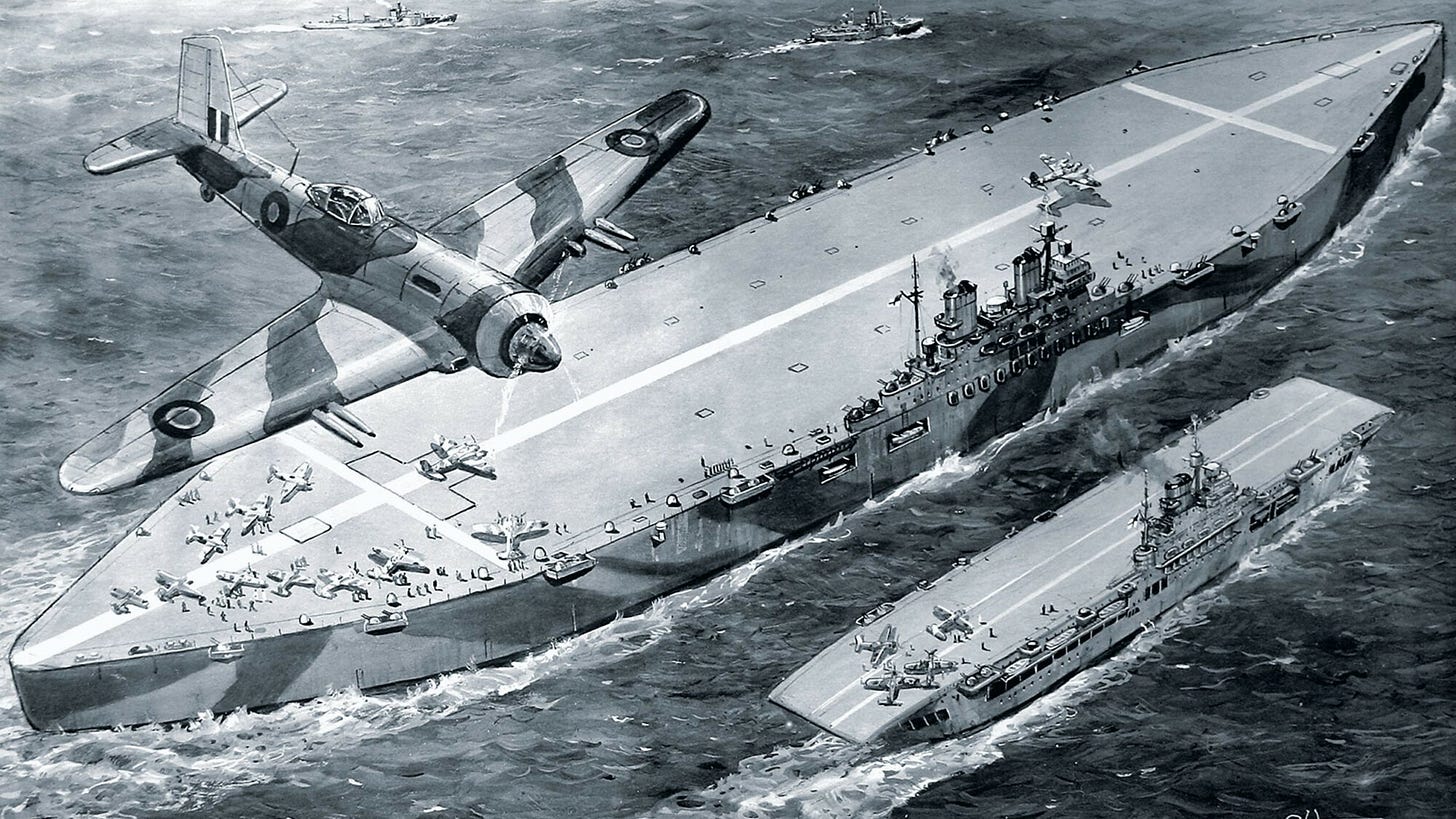

In the annals of military history, few projects have captured the imagination quite like Project Habakkuk—Britain's audacious wartime scheme to construct an enormous aircraft carrier from ice. Born from the desperate circumstances of the Second World War and the brilliant, if eccentric, mind of Geoffrey Pyke, this extraordinary venture represented one of the most unconventional solutions ever proposed to the U-boat menace that was strangling Allied shipping lanes across the Atlantic.

The project was a plan by the British during the Second World War to construct an aircraft carrier out of pykrete, a mixture of wood pulp and ice, for use against German U-boats in the mid-Atlantic, which were beyond the flight range of land-based planes. What began as an almost fantastical idea would eventually involve some of Britain's finest scientific minds, consume considerable wartime resources, and leave behind a legacy that continues to fascinate historians and engineers alike.

The Genesis of an Extraordinary Idea

The Strategic Context

By 1942, the Battle of the Atlantic had reached a critical juncture. German U-boats were wreaking havoc on Allied merchant shipping, operating with near-impunity in the vast expanses of the mid-Atlantic—areas beyond the effective range of land-based Allied aircraft. Nazi submarines, out of the range of Allied warplanes, ruled the day in an area of the Atlantic Ocean known as "U-boat alley". The absence of air cover in this critical region, often referred to as the "Atlantic Gap," meant that merchant vessels were vulnerable to submarine attack for days at a time during their transatlantic crossings.

Traditional aircraft carriers, whilst effective, were expensive to build, required enormous quantities of steel—a precious wartime commodity—and took considerable time to construct. Moreover, they were themselves valuable targets that required extensive escort protection. The Royal Navy desperately needed a solution that could provide air cover in the mid-Atlantic without the prohibitive costs and vulnerabilities of conventional carriers.

Geoffrey Pyke: The Unconventional Inventor

Enter Geoffrey Pyke, one of Britain's most eccentric wartime inventors. Working at a branch of the British War Office in 1942, this brilliant but unconventional scientist was tasked with finding innovative solutions to protect Allied shipping. Pyke possessed a remarkable ability to approach problems from entirely unexpected angles, often proposing solutions that seemed absurd until their underlying logic became apparent.

Pyke's background was as unconventional as his ideas. A journalist turned inventor, he had previously worked on other ambitious wartime projects, including the ill-fated Project Plough—a scheme to create elite ski troops for operations in Norway. His tendency to clash with military bureaucracy and his unorthodox methods often put him at odds with more conventional minds, but his innovative thinking had earned him a place within Britain's wartime scientific establishment.

The Ice Ship Concept

Pyke named his grandiose scheme after the prophet Habakkuk, who said: "I will work a work in your days which ye will not believe, though it be told you". The biblical reference was apt—few would believe the audacious nature of what Pyke was proposing.

The concept was elegantly simple in its basic premise: if steel was scarce and expensive, why not use a material that was abundant, cheap, and readily available—ice? Ice required relatively little energy to produce, so why not use ice instead of steel? Pyke envisioned a giant aircraft-carrying vessel over a mile long with a solid hull made of ice.

However, Pyke quickly recognised that ordinary ice would be wholly inadequate for such an ambitious undertaking. Pure ice was brittle, prone to cracking, and would melt far too quickly in the relatively warm waters of the Atlantic. Initial tests quickly revealed a host of problems with using plain ice, including rapid melting. What was needed was something stronger, more durable, and more resilient to the maritime environment.

The Development of Pykrete

A Revolutionary Composite Material

Geoffrey Pyke developed the idea to blend ice and wood chips together. After some experimentation, they hit on the right mixture. The resulting material, pykrete, was a frozen ice composite, originally made of approximately 14% sawdust or some other form of wood pulp and 86% ice by weight.

The idea came fairly late on (Spring 1943) from an American group that were called in to work on the project, and they christened the composite of ice and wood pulp 'Pykrete' after the prime mover. This naming convention reflected both the material's origins and its creator's central role in the project's development.

The properties of pykrete were genuinely remarkable. Pykrete was much stronger than plain ice, and took much longer to melt—months if not years out on the open ocean. And of course Pykrete, being lighter than water, would naturally float. This strange new material was stronger than concrete, resistant to bullets and torpedoes, and melted significantly slower than traditional ice.

Material Properties and Testing

The mechanical properties of pykrete were extraordinary. Laboratory tests revealed that the material possessed a compressive strength superior to that of concrete, whilst remaining significantly lighter. The wood fibres acted as reinforcement, creating a composite structure that was remarkably resistant to impact and penetration. When subjected to small-arms fire, bullets would embed themselves in the material rather than penetrating through it, whilst the slow melting rate meant that even if damaged, a pykrete vessel would remain seaworthy for extended periods.

Pykrete represented a sustainable composite material, based on a combination of sawdust and frozen water. To build it, you only needed wood and water, both eminently sustainable sources. And to recycle the composite, you simply stopped cooling it. This sustainability aspect was particularly appealing in wartime Britain, where resource conservation was paramount.

The thermal properties of pykrete were equally impressive. The wood pulp acted as insulation, dramatically reducing the rate of heat transfer and thus melting. Even in relatively warm conditions, pykrete structures could maintain their integrity for months, provided they were of sufficient mass and thickness.

Project Habakkuk Takes Shape

Churchill's Enthusiasm

In December 1942, Prime Minister Churchill issued a directive that research on the project should be pressed forward with the highest priority, expressing the opinion that nature should be allowed to do as much of the work as possible. Churchill's enthusiasm for unconventional solutions to wartime problems was well-documented, and the ice ship concept clearly captured his imagination.

The Prime Minister's support was crucial in securing the resources and priority necessary to advance the project. Geoffrey Pyke assured Winston Churchill that the aircraft carrier could be built in as little as 14 days and would be completed by 1944. The British prime minister ordered a single ship, with a promise of more if the first was successful.

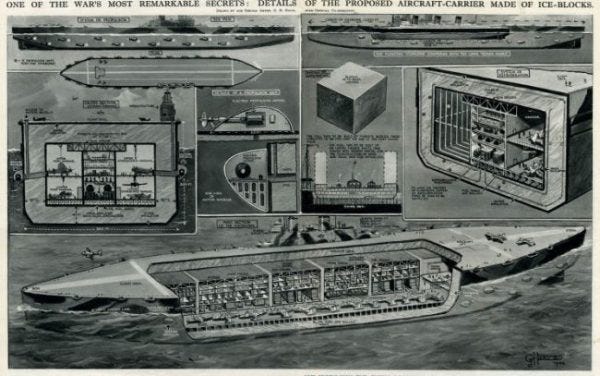

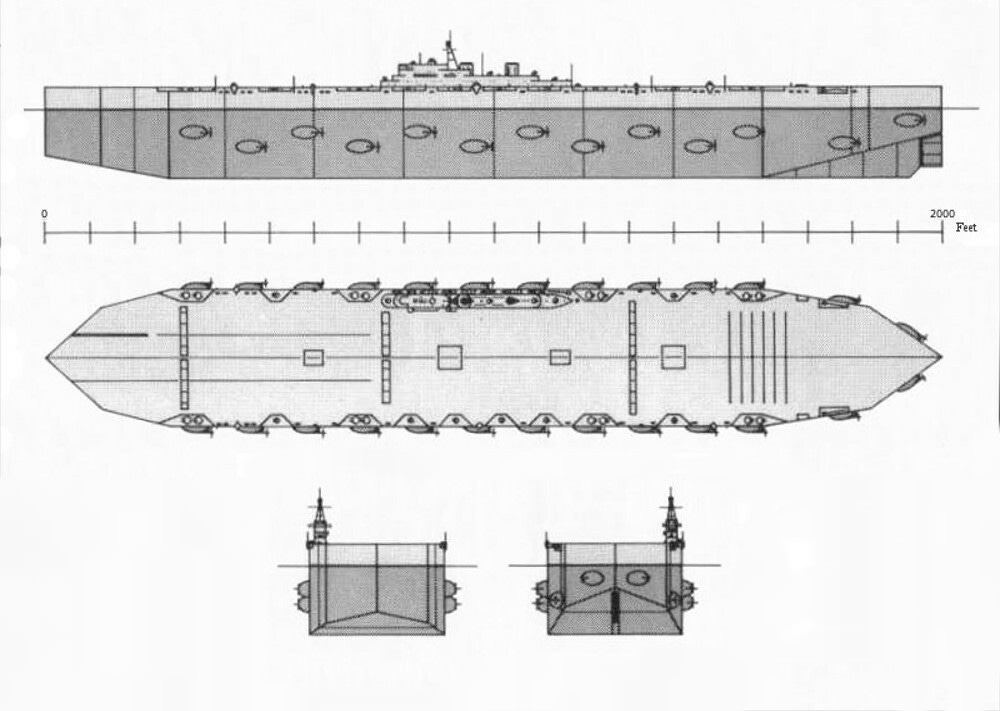

Design Specifications

The proposed Habakkuk vessel was to be truly gargantuan in scale. The design featured a long landing platform along the top and central void running its length below. The specifications called for a vessel approximately 2,000 feet (610 metres) in length, 300 feet (91 metres) in breadth, and 200 feet (61 metres) in depth. The flight deck alone would measure some 2,000 by 700 feet, providing ample space for aircraft operations.

The hull would be constructed entirely of pykrete, with a thickness of approximately 40 feet (12 metres) to provide adequate structural integrity and resistance to torpedo attack. Internal compartments would house aircraft hangars, crew quarters, workshops, and all the necessary facilities for sustained operations. The vessel would be equipped with a sophisticated refrigeration system to maintain the structural integrity of the pykrete hull in all climatic conditions.

The proposed armament was equally impressive. Plans called for numerous anti-aircraft guns and defensive positions distributed throughout the superstructure. The vessel would carry a complement of fighter aircraft and bombers, providing both defensive capabilities and offensive striking power against submarine targets.

International Collaboration

Recognising that the project's scale exceeded Britain's wartime industrial capacity, efforts were made to secure American participation. Pyke was excluded from the planning for Habakkuk in an effort to secure American participation, a decision that Bernal supported. Pyke's earlier disagreements with American personnel on Project Plough, which had caused his removal from that project, were the main factor in this decision.

This decision to side-line the project's originator reflected the pragmatic realities of wartime collaboration. American industrial capacity and resources would be essential to realising such an ambitious undertaking, but Pyke's abrasive personality and previous conflicts with American officials were seen as potential obstacles to cooperation.

The involvement of American scientists and engineers brought additional expertise and resources to the project. Their contribution to the development of pykrete technology was particularly significant, as they refined the material composition and manufacturing processes that would be necessary for large-scale construction.

Testing and Prototyping

The Canadian Experiments

With the theoretical foundations established, attention turned to practical testing. Patricia Lake, named after Princess Patricia of Connaught, a granddaughter of Queen Victoria, was selected as the site of wartime experiments examining the feasibility of building an aircraft carrier out of ice. The remote location in the Canadian Rockies provided the necessary secrecy and appropriate climatic conditions for testing.

They built a prototype ship that was 60 feet or 18 metres long and weighed 1,000 tons. It had walls made of wood and tar with refrigeration pipes in the walls of the ship. This scale model, whilst tiny compared to the proposed full-size vessel, was substantial enough to provide meaningful data about the behaviour of pykrete structures in aquatic environments.

The extraordinary idea of constructing large platforms or ships out of ice took hold in WW2 and small scale experiments were undertaken on Patricia Lake near Jasper in the Rocky Mountains. Sawdust would be added to the water before freezing to greatly increase its strength.

Prototype Performance

The Patricia Lake prototype provided valuable insights into the practical challenges of pykrete construction. The refrigeration system, essential for maintaining structural integrity, proved to be both complex and energy-intensive. The prototype successfully demonstrated that pykrete structures could indeed float and maintain their integrity over extended periods, but it also revealed the enormous logistical challenges that would be involved in scaling up to a full-size vessel.

The testing programme examined various aspects of pykrete performance, including structural strength, thermal properties, resistance to damage, and long-term stability. The results were generally encouraging, confirming many of the theoretical predictions about the material's properties. However, they also highlighted practical difficulties that would need to be overcome for successful implementation.

The refrigeration unit supposedly still sits at the bottom of Lake Patricia, a physical reminder of this extraordinary wartime experiment. The prototype vessel itself eventually melted away, but not before providing crucial data for the project's continuation.

Technical Challenges and Engineering Solutions

Refrigeration Systems

One of the most significant technical challenges facing Project Habakkuk was the development of an adequate refrigeration system. Maintaining the structural integrity of a pykrete vessel in the variable temperatures of the Atlantic would require a sophisticated network of cooling pipes and refrigeration units distributed throughout the hull.

The energy requirements for such a system were enormous. Calculations suggested that the refrigeration plant alone would require the equivalent of several large ship's engines, significantly impacting the vessel's overall power requirements and operational range. The complexity of the refrigeration system also raised concerns about reliability and maintenance in operational conditions.

Engineers explored various solutions, including the use of seawater for cooling and the development of more efficient refrigeration technologies. The integration of the cooling system with the vessel's structure presented additional challenges, as the pipes and equipment had to be embedded within the pykrete hull without compromising its structural integrity.

Construction Methodology

The construction of a full-size Habakkuk vessel would require entirely new building techniques. Traditional shipyard facilities would be wholly inadequate for constructing a vessel of ice and wood pulp. Specialised facilities would need to be developed, capable of handling the unique requirements of pykrete construction.

The construction process would likely involve building massive moulds or forms, into which the pykrete mixture would be poured and allowed to freeze. The timing and sequencing of this process would be critical, as different sections would need to be integrated whilst maintaining structural continuity. The installation of internal systems, including the refrigeration network, would need to be coordinated with the construction of the hull itself.

Weather conditions would play a crucial role in construction scheduling. Ideally, construction would take place in cold climates where natural freezing could assist the process, but this would limit the available construction sites and potentially complicate logistics and supply chains.

Operational Considerations

Beyond construction challenges, the operation of a pykrete aircraft carrier would present unique difficulties. The vessel's enormous size would limit the ports it could visit, whilst its unconventional construction would require specially trained crew members familiar with pykrete maintenance and repair procedures.

Aircraft operations would need to account for the unique properties of the pykrete flight deck. Landing and takeoff procedures might need modification, whilst aircraft maintenance and storage would require consideration of the vessel's thermal management systems. The integration of traditional naval systems with the unconventional hull material would require extensive redesign of standard equipment and procedures.

Navigation and manoeuvring of such a massive vessel would present additional challenges. The size and mass of the proposed Habakkuk would make it extremely difficult to manoeuvre, particularly in confined waters or adverse weather conditions. The vessel's seakeeping qualities in rough weather were also uncertain, given the unprecedented nature of its construction.

The Decline of Project Habakkuk

Changing Strategic Circumstances

As 1943 progressed, several factors began to work against Project Habakkuk's continuation. Most significantly, improvements in aircraft range and the development of escort carriers were providing alternative solutions to the mid-Atlantic air coverage problem. The project was never built as the practicalities involved were too much for the British war effort.

The introduction of Very Long Range (VLR) aircraft, including modified B-24 Liberators, began to close the Atlantic Gap that had provided the original justification for the ice ship concept. Similarly, the mass production of escort carriers—small aircraft carriers converted from merchant vessels—offered a more conventional and immediate solution to the air coverage problem.

Resource Allocation Pressures

The enormous resource requirements of Project Habakkuk became increasingly difficult to justify as other wartime priorities demanded attention. The project produced a dislocation of the Allied effort to a significant extent, despite none of the other wartime inventions achieving such disruption. The human resources, materials, and industrial capacity required for Habakkuk could potentially be better utilised in other, more immediately pressing military projects.

The complexity and uncertainty surrounding the project also made it a difficult proposition for resource allocation committees. Unlike conventional weapons systems with proven track records, Habakkuk represented a leap into the unknown, with no guarantee of successful completion or operational effectiveness.

Technical Realities

As detailed engineering studies progressed, the technical challenges became ever more daunting. The refrigeration requirements alone threatened to consume enormous amounts of energy and resources. The logistics of construction, maintenance, and operation in wartime conditions appeared increasingly problematic.

The time required to develop and test the necessary technologies was also working against the project. While the initial cost of production was significant, and Geoffrey Pyke had promised completion by 1944, it became apparent that this timeline was overly optimistic. By the time Habakkuk could be completed and operational, the strategic situation might have changed substantially.

Scientific Legacy and Historical Significance

Materials Science Innovation

Despite its ultimate cancellation, Project Habakkuk made significant contributions to materials science and engineering. The development of pykrete represented an early example of composite material engineering, anticipating many of the principles that would later be applied in aerospace and construction industries.

The research into pykrete's properties provided valuable insights into the behaviour of fibre-reinforced composites, thermal management in extreme environments, and the challenges of scaling laboratory materials to industrial applications. These lessons would prove valuable in post-war materials development, even if not directly applicable to naval construction.

Engineering Ambition

Project Habakkuk exemplified the spirit of wartime innovation, where conventional thinking was set aside in favour of radical solutions to pressing problems. The willingness to explore seemingly impossible concepts, combined with rigorous scientific investigation, represented the best aspects of wartime research and development.

The project demonstrated both the potential and the limitations of ambitious engineering projects. Whilst the technical challenges ultimately proved insurmountable within wartime constraints, the systematic approach to problem-solving and the integration of multiple scientific disciplines provided valuable lessons for future large-scale engineering endeavours.

Historical Context

In the broader context of the Second World War, Project Habakkuk represented one of many unconventional weapons projects pursued by belligerent nations. From German V-weapons to American atomic research, the conflict saw unprecedented investment in revolutionary military technologies. Habakkuk, whilst ultimately unsuccessful, was part of this broader pattern of innovation under pressure.

The project also illustrated the challenges of international cooperation in wartime research and development. The tensions between British innovation and American industrial capacity, exemplified by Geoffrey Pyke's exclusion from later project phases, would be repeated in many other collaborative efforts throughout the war.

Contemporary Relevance and Modern Applications

Sustainable Materials

In an era of increasing environmental consciousness, pykrete's properties as a sustainable, recyclable composite material have attracted renewed interest. The material represented a sustainable composite, requiring only wood and water as raw materials, with the ability to recycle it simply by stopping the cooling process.

Modern materials scientists have revisited pykrete and similar bio-composites for applications ranging from temporary construction to emergency shelter materials. The principles underlying pykrete—combining abundant natural materials to create enhanced properties—remain relevant to contemporary sustainable materials research.

Engineering Education

Project Habakkuk continues to serve as an excellent case study in engineering education, demonstrating both the importance of innovative thinking and the need for rigorous analysis of practical constraints. The project illustrates how even seemingly absurd ideas can contain valuable insights, whilst also showing the importance of considering all aspects of a complex engineering system.

The multidisciplinary nature of the project, involving materials science, mechanical engineering, naval architecture, and logistics, makes it an ideal subject for teaching systems engineering approaches to complex problems.

Conclusion

Project Habakkuk stands as one of the most extraordinary chapters in the history of military engineering. Born from the desperate circumstances of wartime and the brilliant imagination of Geoffrey Pyke, the ice aircraft carrier concept pushed the boundaries of what was considered possible in naval construction.

The project represented an attempt to add a new element of war—ice—to the traditional materials of steel and explosives. Whilst ultimately unsuccessful, the systematic investigation of pykrete's properties and the serious consideration given to such an unconventional solution demonstrate the remarkable creativity and scientific rigour that characterised Britain's wartime research efforts.

The technical innovations developed during the project, particularly in the field of composite materials, contributed to post-war developments in materials science. The refrigeration and thermal management systems designed for Habakkuk provided insights that would prove valuable in other applications. Perhaps most importantly, the project exemplified the willingness to think beyond conventional solutions when facing seemingly insurmountable challenges.

Project Habakkuk may have remained unrealised, but its legacy endures as a testament to human ingenuity and the power of scientific investigation. In an age when environmental concerns and resource constraints are driving innovation in materials and construction, the principles underlying Pyke's ice ship may yet find new applications.

The remains of the prototype vessel may lie at the bottom of Patricia Lake, and the refrigeration equipment may still rest on the lake bed, but the spirit of innovation that drove Project Habakkuk continues to inspire engineers and scientists facing today's challenges. In the words of the biblical prophet after whom the project was named, it truly was "a work which ye will not believe, though it be told you"—a fitting epitaph for one of history's most ambitious and extraordinary engineering ventures.

The story of Project Habakkuk serves as a reminder that in times of crisis, the most unconventional ideas may offer the most promising solutions. Whilst practical constraints may ultimately prevent their realisation, the act of seriously investigating radical alternatives can lead to unexpected discoveries and innovations that benefit future generations. In this light, Project Habakkuk was not a failure, but rather a bold step into the unknown that expanded the boundaries of what engineers and scientists considered possible.